Geochem Engineering provides onsite testing in lining projects and performs many different types of tests to ensure that the geomembranes that installs delivered to the client to an excellent performance.

The main categories of the tests we perform are:

All field seams could be non-destructively tested. There are different test methods available to test all types of geomembrane seams. Specific test methods are required for each geomembrane due to the physical properties of the geomembrane.

The air pressure test is performed on seams prepared with a double wedge welding machine. The double wedge welder prepares two welds separated by an unbonded channel. This channel is sealed at both ends and pressurized. A drop in air pressure indicates an unbonded area which is then located and repaired with a patch and tested again. A seam that holds its pressure for the prescribed period (a drop less than 10% after 5 minutes is accepted) indicates that the seam is fully bonded (thickness of the material may cause variance). The air is then released from the opposite end from where it was pressurized in order to verify that the tested seam is continuous. Details of the air pressure test are in ASTM D5820.

For vacuum testing, the following procedures are applicable to those seams welded with an extrusion welder.

The equipment used shall consist of a vacuum pumping device, a vacuum box and a foaming agent in solution. Wet a section with the foaming agent, place vacuum box over wetted area. Evacuate air from the vacuum box to a pressure suitable to affect a seal between the box and geomembrane. Observe the seam through the viewing window for the presence of soap bubbles emitting from the seam. If no bubbles are observed move the box to the next area for testing. If bubbles are observed, mark the area of the leak for repair and re-test.

For welds prepared in thin films, or in seams prepared with a solid wedge welder (without a testing channel) an air lance test may be appropriate. An air lance directs a nozzle of compressed air at the seam overlap. Any through defects will show as an inflated channel through the seam. Defects are then marked and repaired. The air lance test is detailed in ASTM D4437.

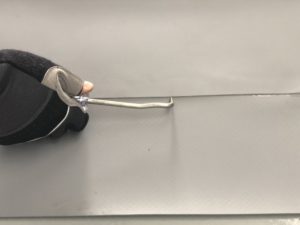

In certain areas such as around pipes and protrusions, it may not be possible to use one of the standard non-destructive tests. In this case a point stress test may be called for. A point stress test uses a thin, blunt object to assist a visual inspection in determining that the seam is continuous.

The test is applicable to seams made by the extrusion method, seams made by using welding tape (a strip of the same type of material as the geomembrane, that is welded over adjacent sections of geomembrane to create a seam), or seams where it is practical to insert a conductive material in the seam just prior to or during fabrication. Before or as the seam is fabricated a continuous electrically conductive material is inserted in the lapped area of the panels 2 to 5 mm (0.1 to 0.2 in.) from the edge of the top panel of membrane. The air lance test is detailed in ASTM D-6365.

A portable tensiometer is taken to site and seam specimens are tested in peel and shear. Seams that do not meet project specifications are repaired and retested. Destructive tests can be performed on qualification welds and on weld samples. Details on destructive testing can be found in ASTM D6392.

Qualification or trial Welds are welds performed on small pieces of project material at site to verify welder settings and performance. Two pieces of material, at least 1m are welded together and specimens tested. If the specimens meet project specifications then main welding procedure may proceed or, if the specimens fail then the equipment is adjusted and re-qualified. Qualification welds are performed:

Weld samples are specimens taken from the installed or under construction geomembrane to verify seem properties and to evaluate bonded seam strength. Seams not meeting specifications are repaired and retested as required.

It is recommended that the specimen removal areas be chosen so as not to require extensive repairs to the geomembrane. Specimens can be taken from the ends of seams, and from seams in the anchor trench.

The unconsidered destruction of a completed geomembrane seam in order to provide test samples is not suggested and must be avoided. Cutting out a specimen from a completed wedge weld that has passed a non-destructive testing (air test) and is bound by two passed qualification welds does nothing to improve the performance of the geomembrane. In addition every destruction cutting creates the need of a repair and a new point of testing.